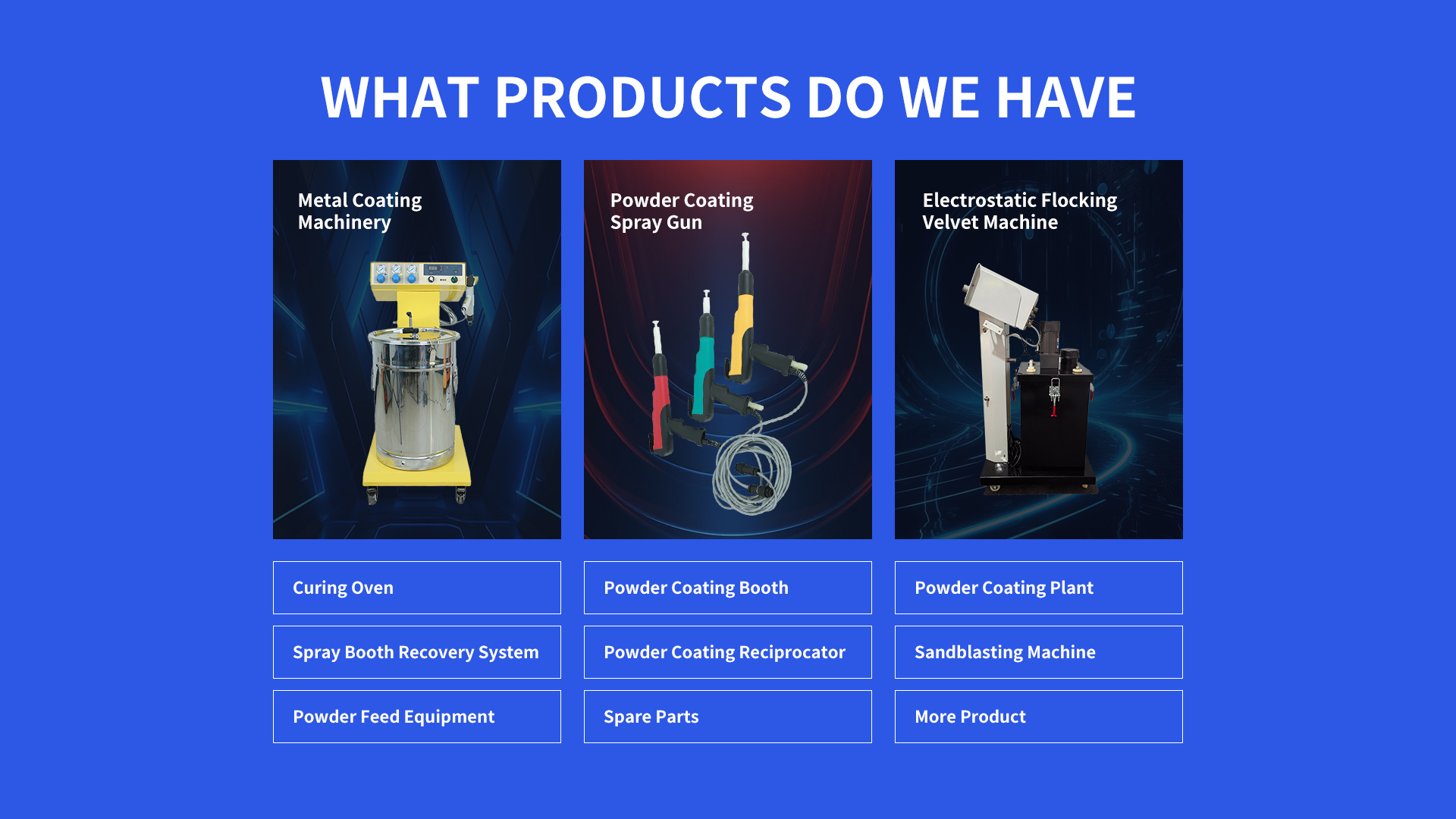

Powder coat spray guns are indispensable tools in the powder coating industry. They come in two main categories:

Priced at approximately $120, these guns are ideal for hobbyists and small - scale DIY enthusiasts. Their design is straightforward, featuring a basic powder - feeding mechanism and standard electrostatic capabilities. This makes them easy to use for those new to powder coating, allowing them to experiment with different projects without a large investment.

Starting at $500, these high - end models are engineered for professionals and industrial applications. They offer a host of advanced features, including variable powder - flow control, which enables precise regulation of the powder output. High - precision electrostatic adjustment ensures optimal adhesion of the powder to the workpiece, and their ergonomic design reduces operator fatigue during long - term use.

These spray guns operate based on the electrostatic principle. As the powder is sprayed, it becomes charged, allowing it to adhere firmly to the grounded workpiece. Constructed from durable materials, they can withstand continuous use in demanding industrial environments. Additionally, most suppliers provide comprehensive user guides, operation video tutorials, and after - sales support for any troubleshooting needs.

Bicycle Customization: Advanced Powder coat spray guns are used to create stunning finishes on bike frames, enhancing their aesthetic appeal.

Small - Scale Metal Handicraft Production: Entry - level guns are perfect for artisans, enabling them to add unique powder coatings to their creations.

Automotive Parts Refurbishment: Depending on the scale of the project, both entry - level and advanced guns are utilized to restore and enhance the appearance of automotive parts.

Ensure the powder container is filled with the appropriate powder.

If it's an electric - powered gun, turn on the power.

Run the gun for a short period to allow the powder to flow through the nozzle.

Carefully disassemble the gun.

Use a compressed air source to clear the clogged powder from the powder - feeding tube and nozzle.

Thoroughly clean all parts before reassembling.

Advanced guns typically have adjustable spray patterns. You can modify the pattern by adjusting the air - flow settings or by using specific nozzles designed for different patterns.

Lubricate moving parts, such as the trigger mechanism, every 10 - 15 uses. Use a lubricant recommended by the manufacturer.

Consider your budget, the complexity of your projects, and how often you'll be using the gun. For occasional small - scale projects, an entry - level gun is sufficient. For regular professional work, an advanced gun offers more features and better performance.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com